Production Steps

Adding Production Steps means that you’ll be able to use the Production area in Manufacturing and also use the Time Tracker for stop/start production tracking.

See also:

- Bills Of Material

- Production

- Time Tracker for Production

- Resources for Manufacturing

- Manufacturing settings

- Creating Manufactured Products

Create Production Steps

1. From Bills Of Material

In Manufacturing > Bills Of Material, open any BoM and go to the Production Steps tab and click on Add Production Step – this adds a step to the relevant BoM.

You can then fill in the details for the step, as per the following field guide.

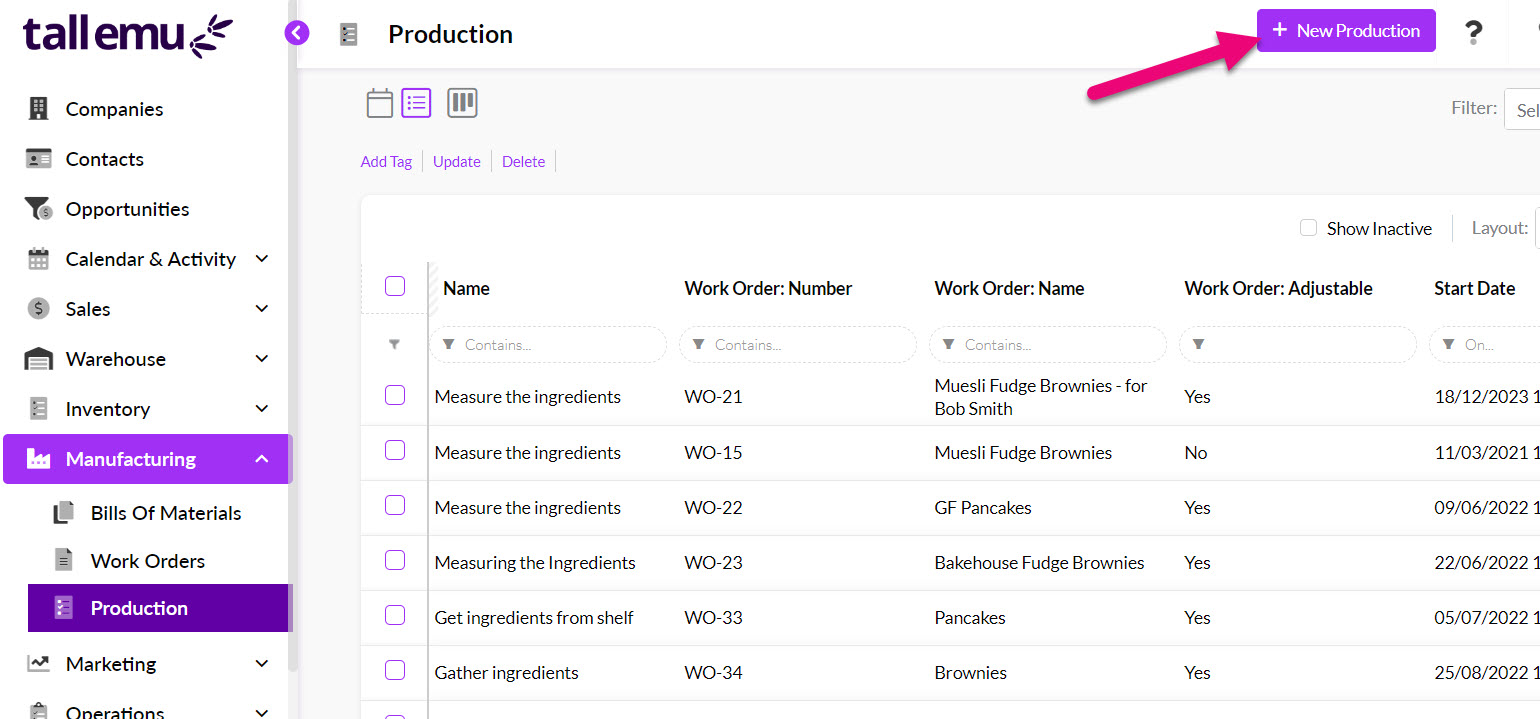

2. From Production

From Manufacturing > Production you can use the New Production button – this adds a step to an existing Work Order.

You can then fill in the details for the step, as per the following field guide.

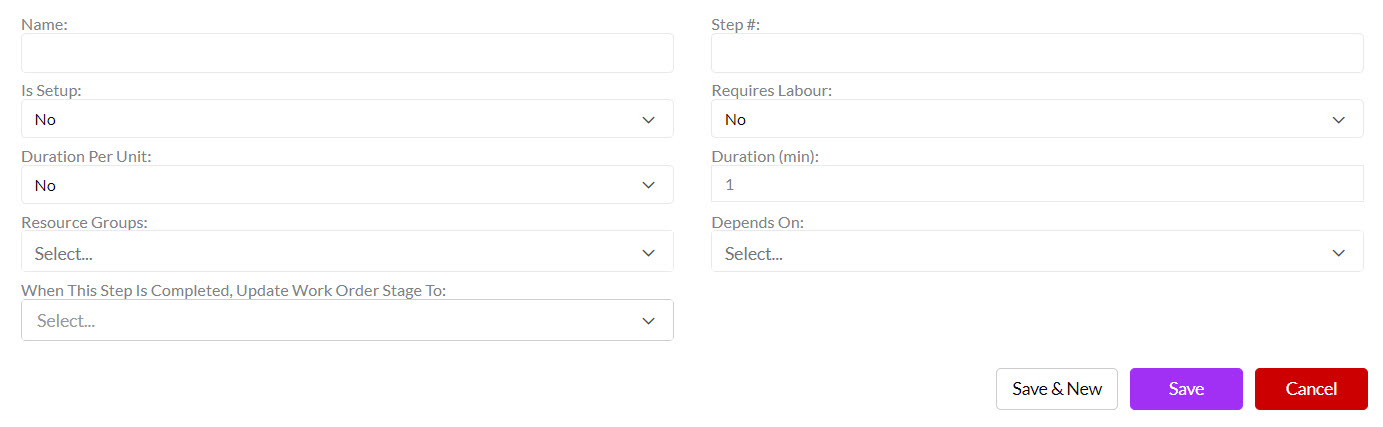

Production Step fields

Following is a list of each field and its purpose.

- Name: give the step a name like “Gather required goods” or “Assemble parts” etc.

- Work Order: select an existing Work Order to link the step to.

- Resource Groups: if you will be using a manufacturing resource as part of the step, you can choose the Group that the Resource comes from here.

- Depends On: this field allows you to select from another step and create a dependency between them i.e. step 2 cannot be started until step 1 is completed.

- Assigned To: choose a User or Team that will be responsible for the step.

- Status: you can select an option from the list here to signify where the step is up to. The options on the list can be customised to suit you.

Status field example on a Production Step

- When This Step Is Completed, Update Work Order Stage To: you can have the system automatically update the Stage field in the Work Order when the step is completed i.e. you may want to have the Work Order Stage updated to something like “In Progress” or “Completed”.

- Is Setup: you can differentiate steps between what is related to production setup and what is an actual production step. By checking this box, you are saying that the step is to do with setup for production. The total duration of the setup steps is calculated and then shown in the Setup Duration field.

Setup Duration field on a BoM

- Requires Labour: you can differentiate steps to mark out ones that require labour.

- For example: a step to “Gather required goods” may need to be performed by a person who physically needs to walk around the factory and collect the items in which case the box would be checked. The step could also be performed by a robot that is programmed to collect the items; in which case the box would remain un-checked as labour is not required.

- Duration (min): this is how long the step will take to perform, in minutes. The total sum of all the step durations is added together with the total time required for setup steps and the total is displayed in the Cycle Duration field i.e. the

- For example: it may take 30 minutes to complete a step called “Assemble parts”.

- Duration Per Unit: you can specify if you want to track the duration per item you are creating or not.

- For example: if I am making 20 brownies and need to box each of them individually. It takes me 1 minute to box a brownie, which I add to the Duration field and then select “Yes” in this field, so that the system will calculate that it takes 20 minutes to box all the brownies i.e. 1 minute x 20 brownies.

Cycle Duration field on a BoM

- Step #: steps for a Work Order are ordered and run numerically (i.e. 1, 2, 3, 4) so add the appropriate number here to signify where the step sits in the overall production process.

Active Production Steps on a Work Order