-

- Inventory

- Multi-currency for Purchasing

- Backorders

- Bay Locations

- Features

- Stock Tracking

- System Products

- Accounting details for Products

- Deactivating Products

- Products in Portal

- Suppliers

- Supplier Pricing

- Suppliers & Products

- Products

- Stock Transfers

- Barcodes

- Product Inventory Details

- Importing & exporting Product data

- Virtual Products

- Stock Adjustments

- Purchase Orders

- Enable or disable Stock-Tracking

- Training Products

- Units of Measure (UoM)

- Freight Products

- Working with Landed Costs

- Configuring Product Settings

- Stock Locations

- Stocktakes

- Product Batches

- Serial Numbers

- Different Price Types

- Purchase Orders

- Managing Stock

- Configurable Products

- Variable Products

- Time Billing

- Manufacturers and Suppliers

- FROM Location-based pricing

- TO Location-based pricing

- Requests For Quote

- Time Products

- Quantity-Based Price Breaks

- RFQ Web Templates

- PO Web Templates

- Location-based Price Breaks

- Customer-Specific Pricing

- Deleting Special Prices

Stock Locations

The Location shown when working with Products is based on information entered when:

- A Product is purchased: a Purchase Order is created and the Purchase For field is used to select a Location for the stock.

- When a shipment for a Purchase Order is marked as received: the stock will automatically increase the In Stock figure at the Location (Purchase For field) that was specified.

- A Product is manufactured: a Work Order is created, and the Location field is used to determine where the Output Products will be stored.

- When the Work Order is completed: the stock will automatically increase the In Stock figure at the Location that was specified.

- Virtual Products: you can specify when a Product is virtual and does not have a fixed Location – when you create a new Product, just tick the Is Virtual box and ensure the Physical box is unticked.

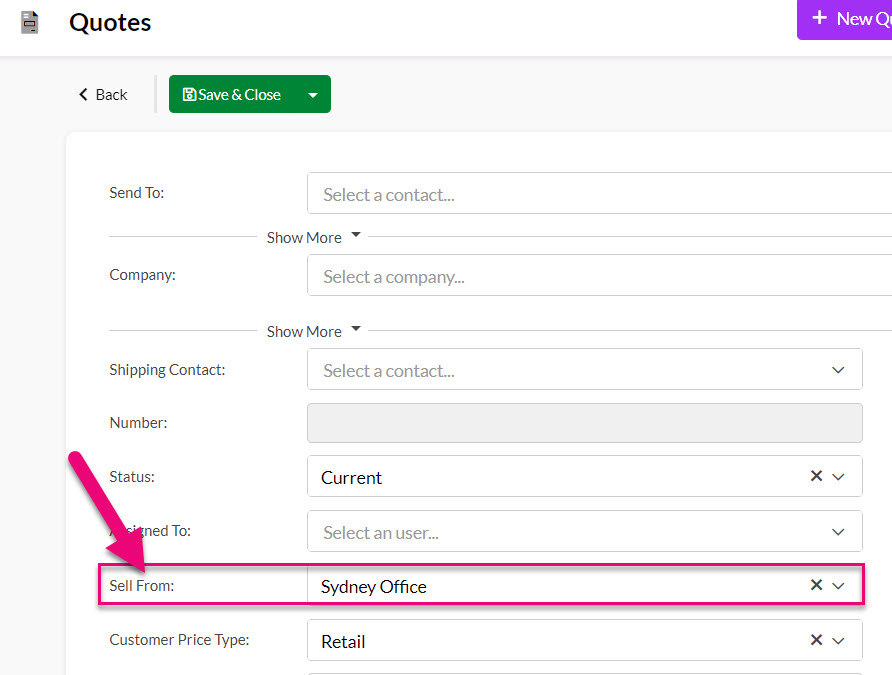

- A Product is sold: a Quote, Sales Order or Invoice is created and the Sell From field is used to select a Location for the stock to be sold from.

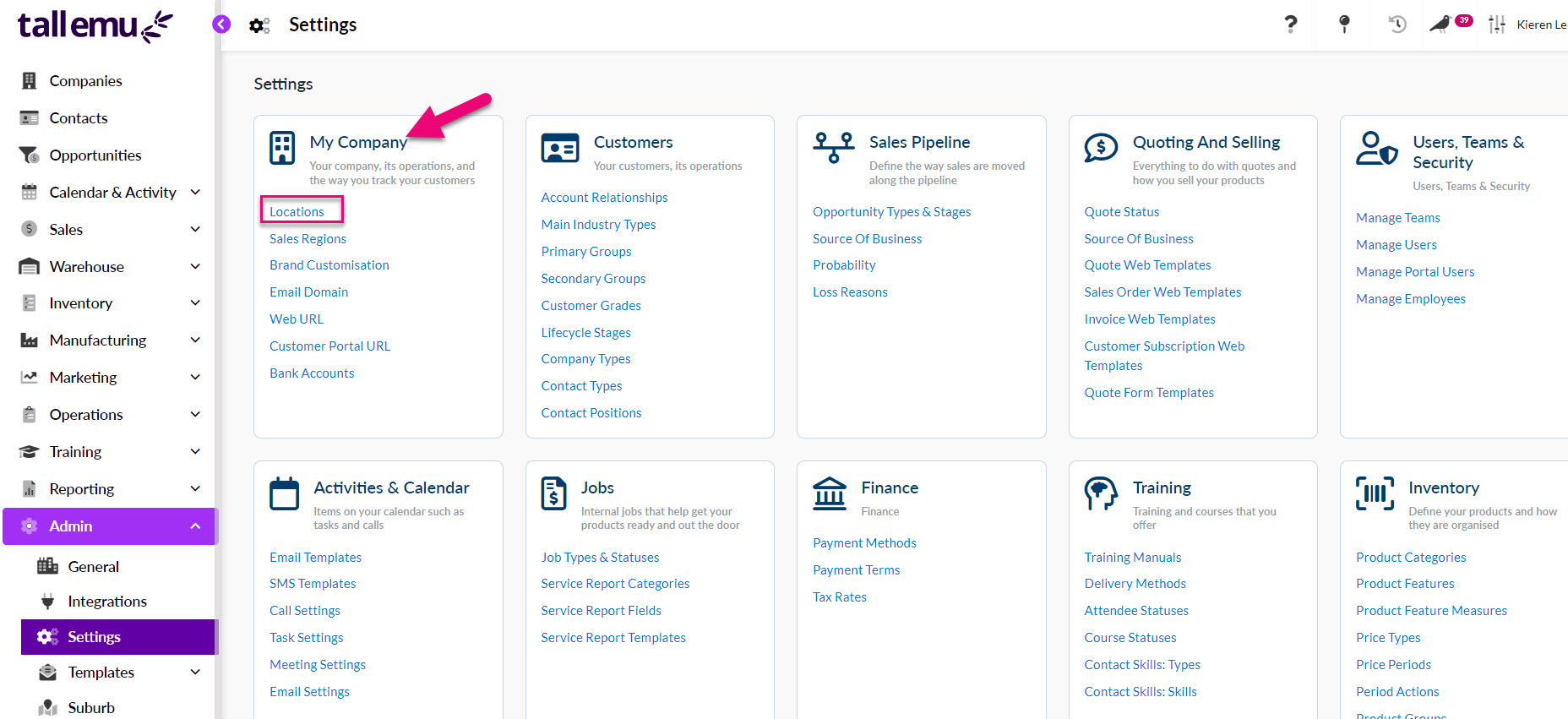

You are able to have multiple stock Locations in CRM.

How this works will depend on the accounting software you are integrated with and how it is configured – please see this guide on Locations for full details.

Stock will automatically be received at the Location that was specified when it was ordered (Purchase Order) or manufactured (Work Order) and the In Stock figure will be increased by the quantity specified on the Purchase or Work Order.

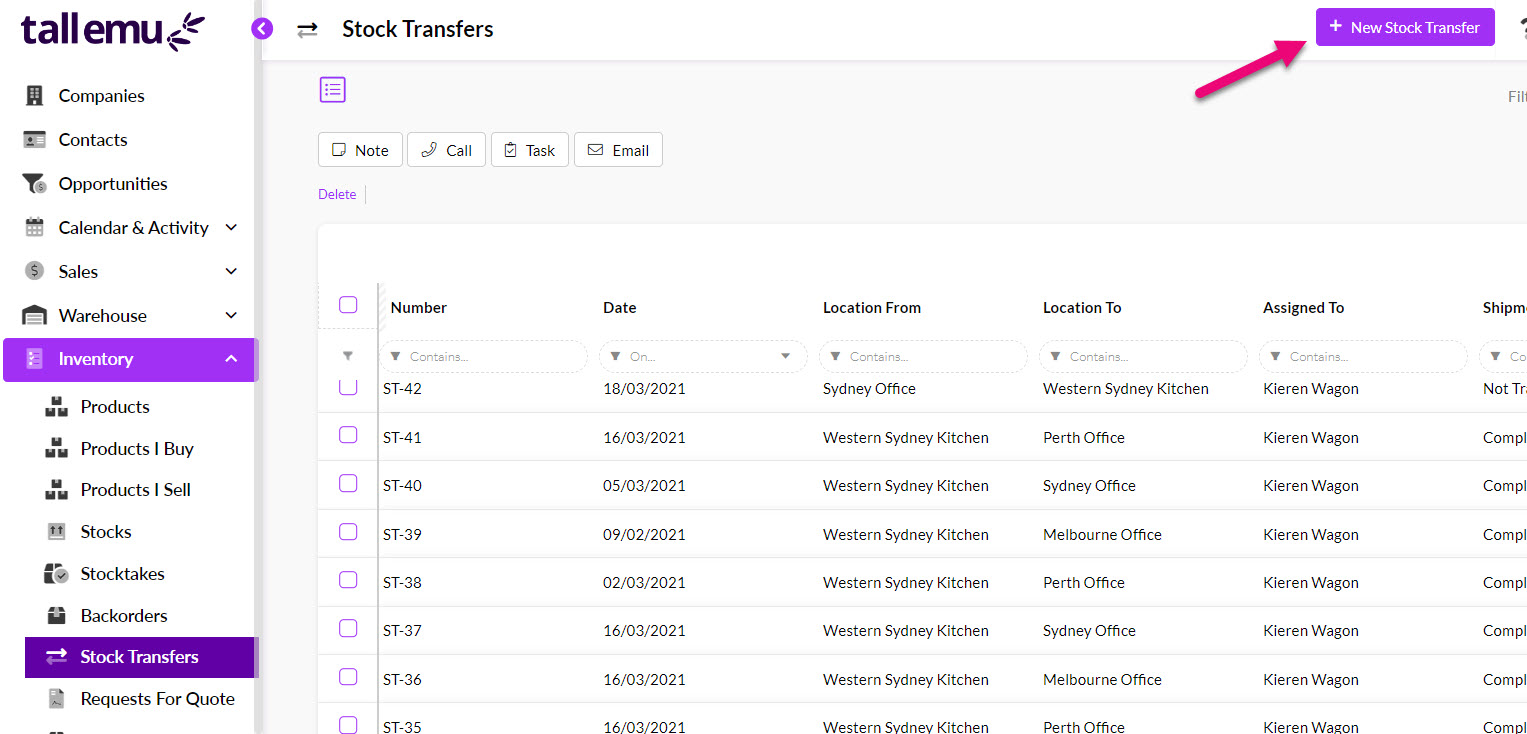

You can move stock between Locations using the Stock Transfers module, which is accessed from within the Warehouse group on the main menu.

When working with Quotes, Sales Orders and Invoices, you can specify the Location that items are being sold from in a few ways:

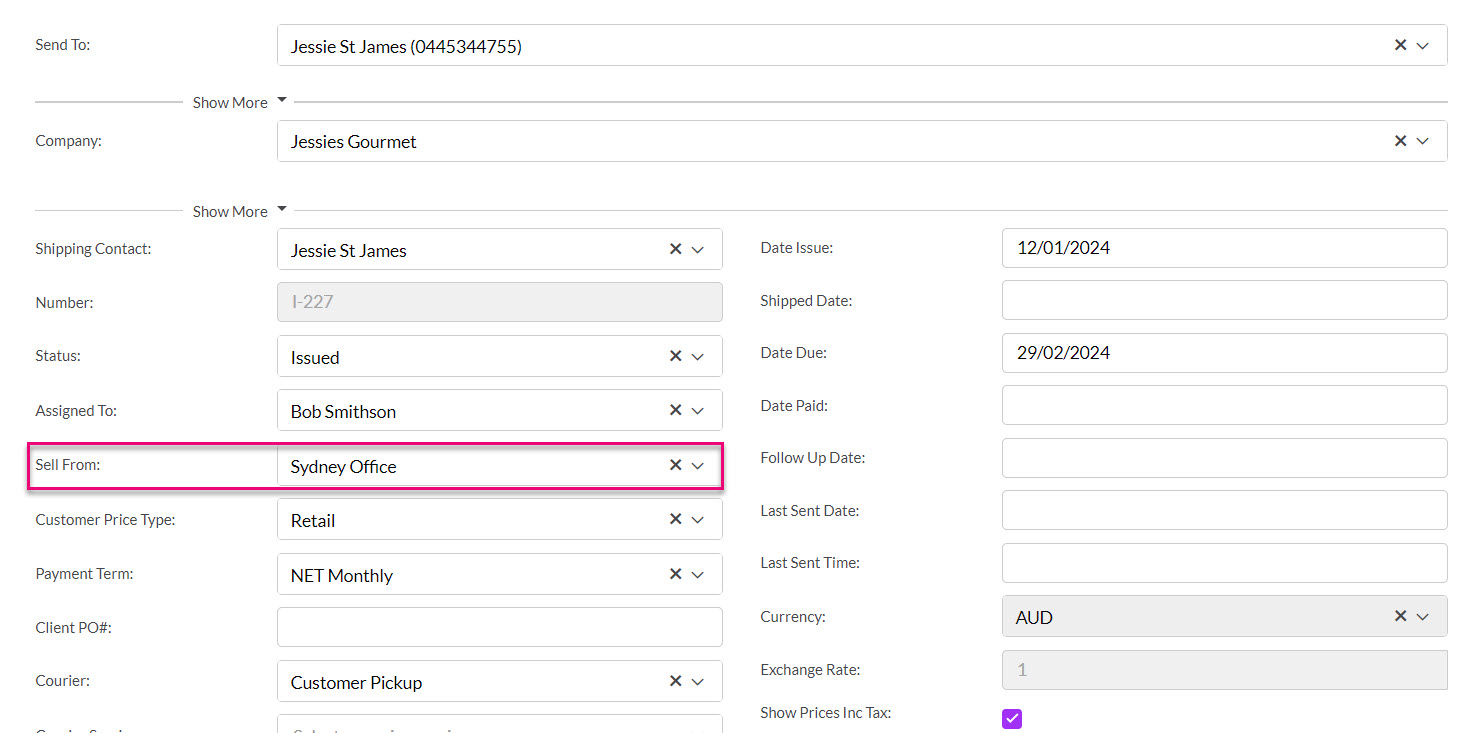

- At an order level, by selecting a Location in the Sell From field.

Sell From Location on a Quote

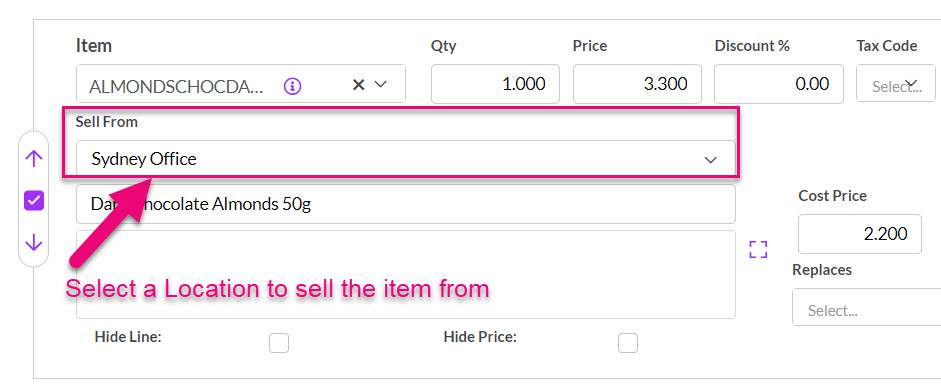

- You can also specify a Location per item, using the Sell From field.

- If using this method, when Outbound Shipments are created from Sales Orders, they will be separated into shipment records based on the location being sold from.

When you select an item, you can then click on the “i” button next to the item name to view stock availability at other Locations.

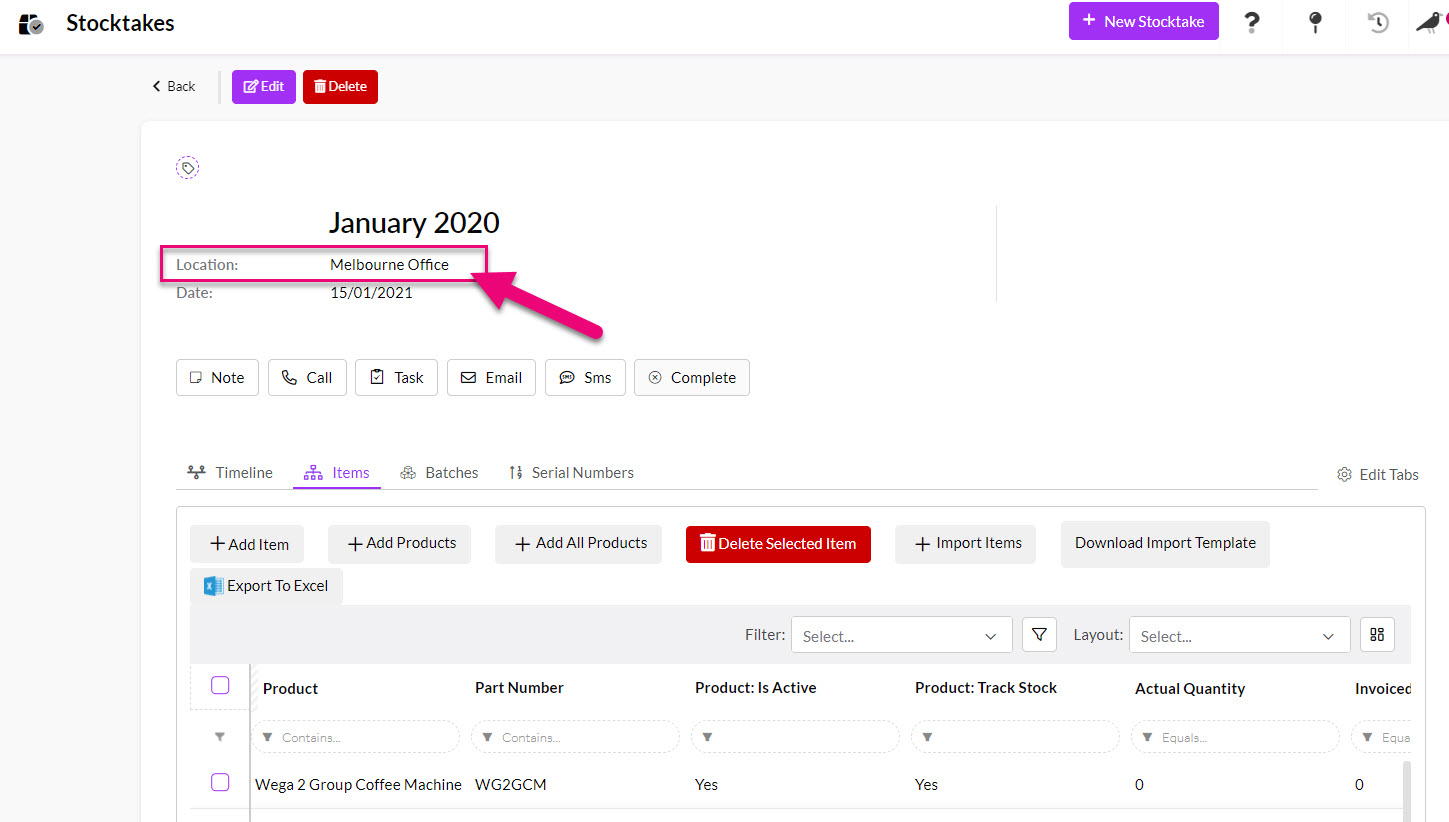

When you create a new Stocktake, you need to choose the Location you are performing it for.